Automated Assembly

Automated Assembly

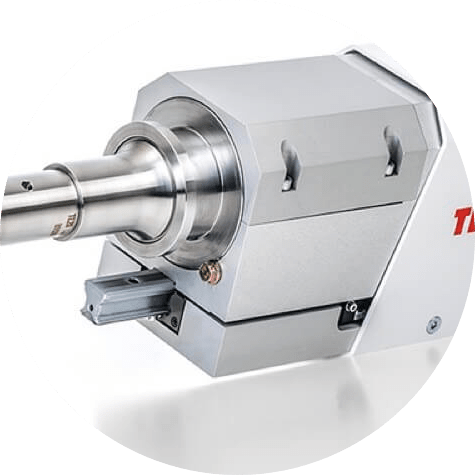

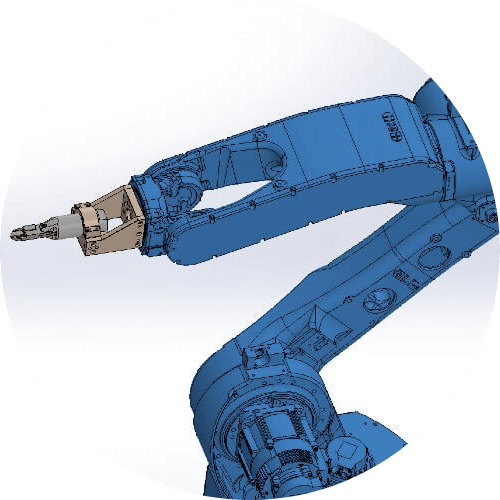

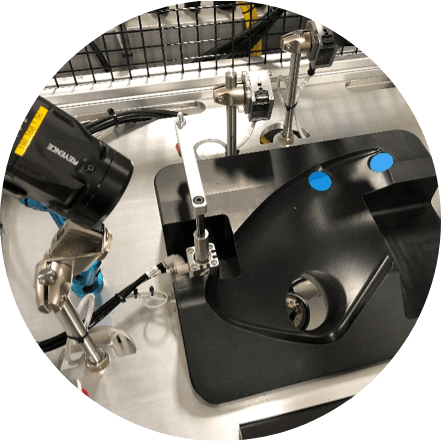

At the right level of product volume, it becomes economically feasible to automate an assembly process. Assemblies with flexible or hard to fixture components require some level of semi-automation with frequent interaction with an operator for loading components and unloading assemblies. Easier to fixture components work well with fully automated assembly. Bowl feed systems for components eliminate the need for individual part feeding from an operator. Indexing conveyors move components quickly and repeatably between process steps. Sensors and vision systems confirm product quality. Automated packing and part counting limit the need for operator interaction. Trust in Chism Automation to build your company an automated process that is built to last and supported by our reliable and experienced group of engineers.