Assembly Lines

Assembly Lines

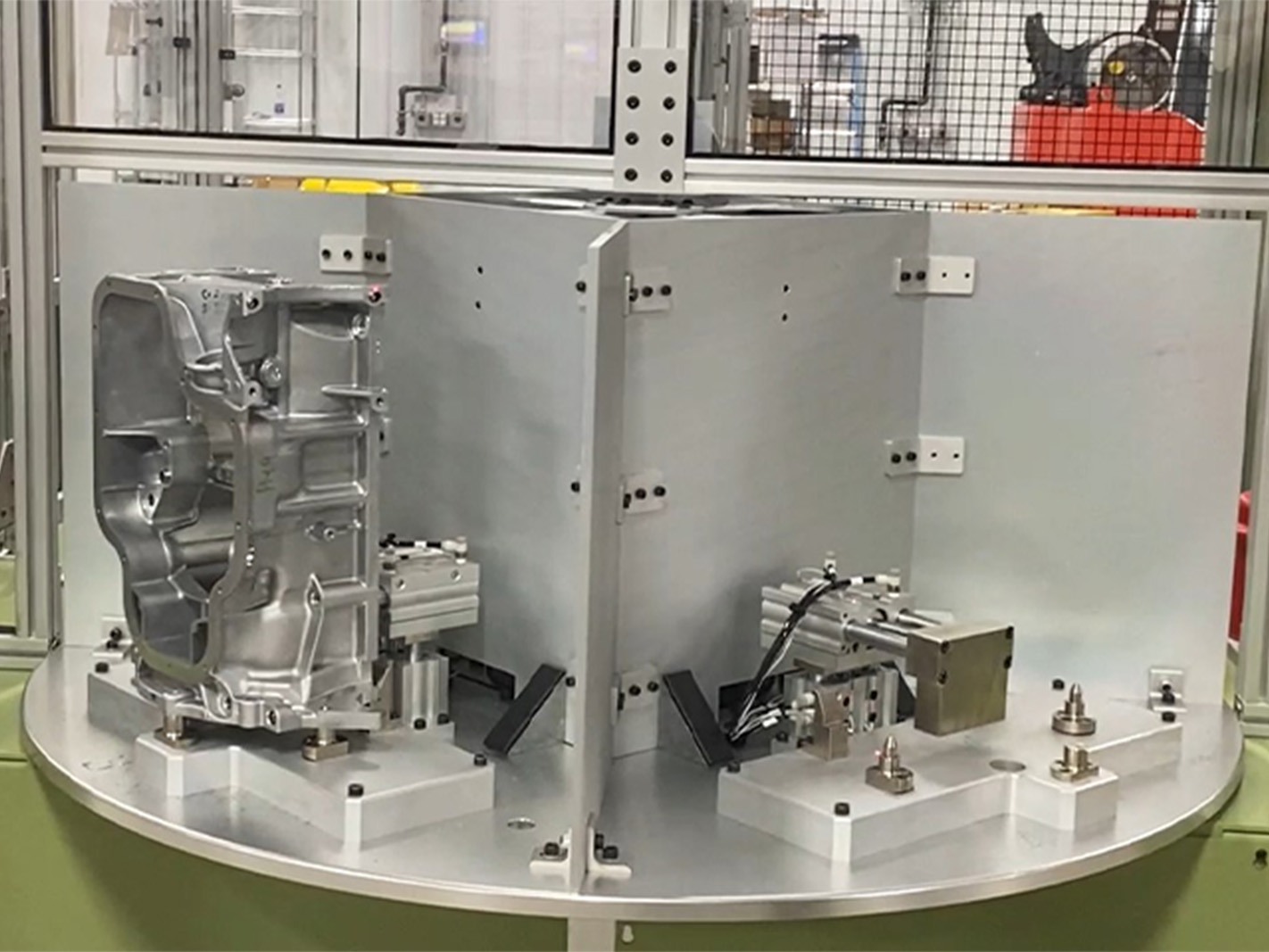

Assembly lines allow for effortless transfer of products between assembly and processing operations. Typical systems are fully automated, semi-automated, or manual. Fully automated systems may include robotics, palletized conveyor lines, and automated feeding systems. Semi-automated systems include a combination of operator and automated processes such as operator loading and robotic processing. Manual assembly lines are operator driven with automated assembly transfer between work stations.

Chism Automation has experience in integrating multiple style systems into a single linear assembly process. Combinations of automated, semi-automated, and manual workstations are offered. Typical projects include some combination of RFID tracking, screw driving, dispensing, pressing, automated assembly, laser marking, traceability system communication, packing, and vision inspection.

Assembly automation standard processes:

Component Introduction

- Manual load

- Bowl feed

- Flex feed with vision assist

- Tray feed

- Pallet feed

- Gravity feed

- Conveyor feed

Material Transfer

- Pallet conveyor

- Belt or roller conveyor

- Indexing conveyor

- Rotary indexer

- Linear actuators

Traceability

- Identification

-

- Laser marking

- Inkjet marking

- Label application

- RFID pallet pairing

-

- Monitoring and data collection

-

- Barcode scanning

- Results assignment

- Automatic dispositioning

-

- Database

-

- Ethernet communication of process results

-

Assembly

- Dispensed materials

- Screwdriving

- Clip application

- Ultrasonic welding

Testing

- Component presence

- Machine vision

- Functional testing

- Leak testing

- Electrical testing

Packing

- Tote packing

- Tote destacking and stacking

- AGV or AMR Logistics

Ready to get started?

Give us a call, or fill out the form below, and a team member will be in touch ASAP to discuss your project.

Phone

(606) 425-0067

Address

1760 Hwy. 80 Somerset, KY 42501